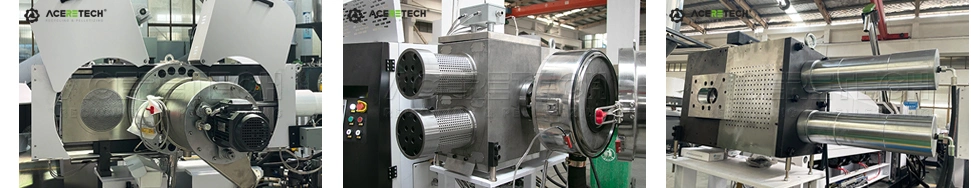

Granules mous de PVC de flocons de PP faisant la ligne de machine

Aperçu Taille du paquet 500,00 cm * 200,00 cm * 200,00 cm Poids brut du colis 2700,000 kg Flocons de PP Granules souples;

Overview

>> Multiple selection of smart feeding method: Plastic scraps can choose belt conveyor; Rolls' scraps can choose roll hauling off device;Feeding speed is automatically.>>> Strong crushing and compacting unit:Rotatory blades of compactor will cut up incoming scraps;Frictional heating will dry and compacts the materials;Feed from the compactor directly into the extruder.Sliding gate make it can handle both film and rigid scraps./p>>> Specialized single screw extruder: Equipped with high torque gearbox with integrated design; 34D to 36D processing section to gently melt the plastics;Bi-metal Screws and barrelsensure 2 times use life than usual.>>> Double-zone vacuum degassing system:Double-zone degassing can remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust./p>>> Plate type double station filter: Cost - effective,Easy to operate;>>> Piston type large area filter:Suitable for heavy contaminated materialSuitable for large capacity recycling machine;>>> SCF type Self-clean filterNo need to change the mesh screen;Automatically discharge the impurities;Can realize 60mesh, 80mesh 100mesh and 120mesh./p>>> For different materials and different usage scenarios, we can provide you different pelletizing systems. Water-ring pelletizing system: Standard granulating method in ACS-H system; Self-adjusting pelletizing head ;RPM of rotatory blades is automatic./p>>> Under-water pelletizing system:Suitable for big capacity, automatically,Applicable to a wider range of materials./p>>> Water-strands pelletizing system:Cost-effective;Suitable for the material which MFI is higher than 8./p>>> Vibration: Sieve is made of Stainless steel ; Dewatering granules and selecting size.Centrifugal dryer:Horizontal-type which is lower energy consumption;Blower on the dryer to remove the moisture further;Equipped with sound-proofing cover to reduce noise.Product silo:All pipes and silos wrapped with sound -proofing cotton;Optional Capacity online monitoring & Quantitative weighing./p>>> Intelligence Start: One button only.>>> Intelligence Stop: One button only.>>> Emergency Stop: One button only.Remote monitoring and information transmission./p>

Informations de base.

| Numéro de modèle. | ACS-H |

| Vis | Vis unique |

| Onduleur | Onduleur |

| Chauffage électromagnétique | Chauffage en céramique ou chauffage à infrarouge lointain |

| Automatisation | Automatique |

| Informatisé | Informatisé |

| Personnalisé | Personnalisé |

| Attestation | CE, ISO9001:2008, TUV |

| Condition | Nouveau |

| Emplacement de l'usine | 2 heures de route de Shanghai |

| Service après-vente | Pièces de rechange gratuites |

| Manuel d'échantillon/service | Disponible |

| Contrôle | Contrôle API |

| Type d'entreprise | Fabricant |

| Matériel | Fer |

| Avantage | Moteur de marque célèbre |

| Produit final | Granulés/granulés |

| Taille de la salle de compactage | 300-1400 L |

| Application | Film, Filament, Raphia, Mousse |

| Tension | 380V 50Hz ou personnalisé |

| Type de machine | Machine de recyclage |

Tu pourrais aussi aimer

Envoyer une demande

Envoyer maintenant